Why Direct to Film (DTF) Printing is new Profit for your printing business?

Why is DTF Printerhot in thecloth printing industry? Compared with large-scaledye sublimation printers, roller machines, and screen printing machines, what advantages the DTF Printing Solution bring to us?

1. What is A Direct To Film Printer? How does A DTF Printer Work?

DTF printer is also known as a digital offset heat transfer and powder shaking machine. It enables you to print the desired design onto a film. Then you transfer it onto the T-shirt, The pattern design is clear and true, which can exceed the actual effect of the photo. Many people named it to offset heat transfer based on Kodak photos. Also known as DTF printer, it is the small family economic printer we are using now.

2. What you need in DTF System?

DTF Ink: A DTF printer comes with several water-based colored ink tanks. Those tanks enable the printer to conveniently manage using CMYK+K settings.

DTF Films: 0.75mm thick, image is printed on film then transfer image to cloth.

Powder Shaker: It applies the powder uniformly and ensures that your designs will not have extra powder patches.

Heat Press Machine: It transfers image printed to fabric.

Hot-melt Adhesive Powder:It’s like desired printing surface for colored pigments.

3. Benefits Of DTF Printers

Compared with DTG printer, DTF Pinter can produce premium-quality prints. No pre-treatment is needed. More printing applications: cotton, polyester, leather and nylon.

Cheaper and time/labor saving.

4. Applications of DTF Printer

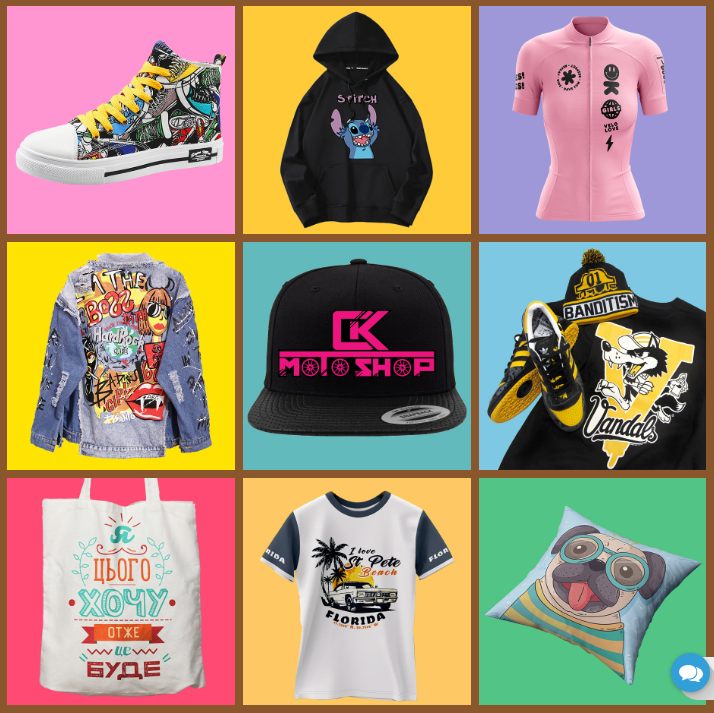

DTF (Direct To Film) is suitable for almost fabric printing(such as jeans, Hats, Coats or hoodies, pants or shorts,etc.)